Reborn Toyota Corolla: How Additive Manufacturing Uplifted a Timeless Icon

Revolutionizing Car Restoration with 3D Printing

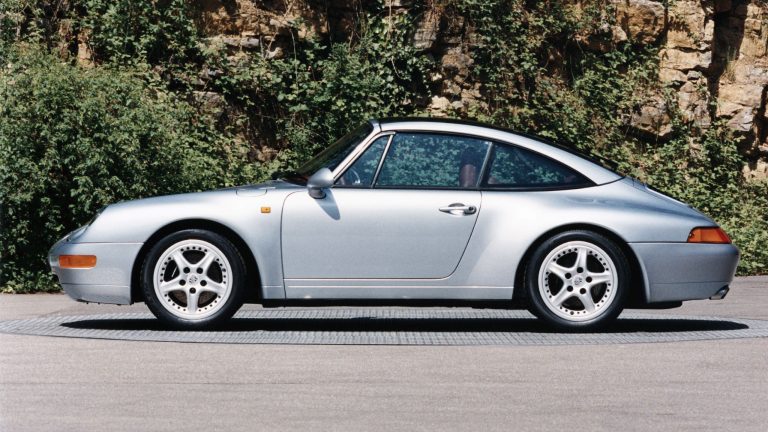

The world of car restoration has undergone a significant transformation with the advent of 3D printing. Gone are the days of scavenging for rare and discontinued parts, as 3D printing has made it possible to create exact replicas of classic car components. In this article, we’ll explore the world of 3D printing in car restoration, focusing on Ryan, the owner of Fat Lip Collective, a Melbourne-based shop that specializes in creating 3D-printed parts for classic cars.

The Art of 3D Printing

Ryan’s passion for 3D printing began with a desire to create a dash insert for his second-gen KE25 Corolla. He wanted the switch panel to look like it could’ve been an optional extra in 1974, with chunky style dash switches inspired by Ferraris and DiTomasos of the 70s and 80s. To achieve this, Ryan spent hours researching, designing, and testing various prototypes.

The Process of 3D Printing

Before diving into the actual printing process, Ryan conducted extensive research to ensure the part fitment was to OE spec. He studied the Toyota dash, taking note of the materials used, such as steel and plastic. This attention to detail allowed him to create a custom piece that replicated the original design while also addressing potential issues.

The Benefits of 3D Printing

One of the significant advantages of 3D printing is its ability to produce complex shapes and designs that would be difficult or impossible to create using traditional manufacturing methods. Ryan’s dash insert is a prime example of this, as it features intricate details and curves that would be challenging to replicate using traditional methods.

The Importance of Originality

Ryan is adamant about preserving the originality of non-replaceable parts. He believes that altering the OE dash would limit his ability to reproduce the part and maintain its authenticity. By creating a custom piece, Ryan can ensure that the dash insert remains faithful to the original design while also providing a unique and functional upgrade.

A Peek into the Future

The future of car restoration is looking bright, thanks to the innovative applications of 3D printing. As technology continues to advance, we can expect to see even more complex and intricate designs being created. Ryan’s passion for 3D printing is a testament to the potential of this technology, and we can’t wait to see what he comes up with next.

Conclusion

The world of car restoration has never been more exciting, thanks to the advent of 3D printing. Ryan’s dedication to creating custom parts that replicate the original design while also addressing potential issues is a shining example of the potential of this technology. As we look to the future, it’s clear that 3D printing will play a significant role in revolutionizing the car restoration industry.

H1: Revolutionizing Car Restoration with 3D Printing

H2: The Art of 3D Printing

- Ryan’s passion for 3D printing began with a desire to create a dash insert for his second-gen KE25 Corolla.

- He spent hours researching, designing, and testing various prototypes.

H2: The Process of 3D Printing

- Ryan conducted extensive research to ensure the part fitment was to OE spec.

- He studied the Toyota dash, taking note of the materials used, such as steel and plastic.

H2: The Benefits of 3D Printing

- One of the significant advantages of 3D printing is its ability to produce complex shapes and designs that would be difficult or impossible to create using traditional manufacturing methods.

H2: The Importance of Originality

- Ryan is adamant about preserving the originality of non-replaceable parts.

- He believes that altering the OE dash would limit his ability to reproduce the part and maintain its authenticity.

H2: A Peek into the Future

- The future of car restoration is looking bright, thanks to the innovative applications of 3D printing.

- As technology continues to advance, we can expect to see even more complex and intricate designs being created.

H2: Conclusion

- The world of car restoration has never been more exciting, thanks to the advent of 3D printing.

- Ryan’s dedication to creating custom parts that replicate the original design while also addressing potential issues is a shining example of the potential of this technology.

Image Captions:

- Figure 1: Ryan’s 3D-printed dash insert prototype

- Figure 2: Ryan’s design process, featuring CAD drawings and 3D models

- Figure 3: The finished dash insert, featuring chunky style dash switches inspired by Ferraris and DiTomasos of the 70s and 80s